Industry News

Revolutionizing Metal Fabrication

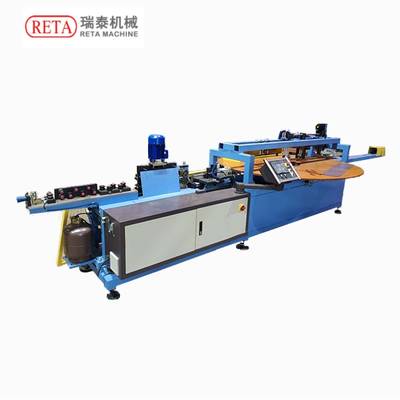

In the dynamic landscape of modern manufacturing, have emerged as indispensable tools, playing a pivotal role in transforming the way metal components are crafted. This article explores the significance and impact of tube bending machines in today's industrial landscape.

Precision Engineering for Complex Shapes

Tube bending machines are at the forefront of precision engineering, enabling the formation of intricate and complex shapes with unparalleled accuracy. With computer numerical control (CNC) technology, these machines execute precise bends, twists, and curves, ensuring consistency and uniformity in the production process.

Versatility in Material Handling

One of the remarkable features of tube bending machines is their adaptability to a wide range of materials. From stainless steel and aluminum to copper and brass, these machines showcase versatility in material handling. This flexibility makes them suitable for diverse industries, including automotive, aerospace, and construction.

Efficiency and Time Savings

In the fast-paced world of manufacturing, efficiency is paramount. Tube bending machines streamline the production process, reducing manual labor and significantly cutting down on production time. The automation capabilities of these machines enhance overall efficiency, allowing manufacturers to meet stringent deadlines and increasing overall output.

Customization Unleashed

The customization potential offered by tube bending machines empowers manufacturers to bring their creative designs to life. Whether creating complex frameworks for machinery or designing aesthetically pleasing architectural elements, these machines provide the freedom to customize products according to specific requirements.

Cost-Effective Manufacturing Solutions

Tube bending machines contribute to cost-effective manufacturing by minimizing material wastage and optimizing production processes. The precise control over the bending process ensures that each component meets exact specifications, reducing the need for rework and material adjustments.

Eco-Friendly Manufacturing Practices

In an era where sustainability is a key consideration, tube bending machines align with eco-friendly manufacturing practices. By minimizing material waste and optimizing energy consumption through automated processes, these machines contribute to a more sustainable and environmentally conscious approach to production.

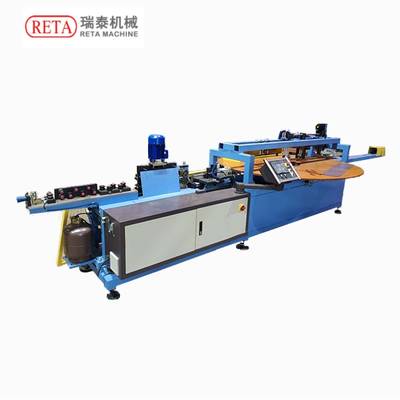

In the dynamic landscape of modern manufacturing, have emerged as indispensable tools, playing a pivotal role in transforming the way metal components are crafted. This article explores the significance and impact of tube bending machines in today's industrial landscape.

Precision Engineering for Complex Shapes

Tube bending machines are at the forefront of precision engineering, enabling the formation of intricate and complex shapes with unparalleled accuracy. With computer numerical control (CNC) technology, these machines execute precise bends, twists, and curves, ensuring consistency and uniformity in the production process.

Versatility in Material Handling

One of the remarkable features of tube bending machines is their adaptability to a wide range of materials. From stainless steel and aluminum to copper and brass, these machines showcase versatility in material handling. This flexibility makes them suitable for diverse industries, including automotive, aerospace, and construction.

Efficiency and Time Savings

In the fast-paced world of manufacturing, efficiency is paramount. Tube bending machines streamline the production process, reducing manual labor and significantly cutting down on production time. The automation capabilities of these machines enhance overall efficiency, allowing manufacturers to meet stringent deadlines and increasing overall output.

Customization Unleashed

The customization potential offered by tube bending machines empowers manufacturers to bring their creative designs to life. Whether creating complex frameworks for machinery or designing aesthetically pleasing architectural elements, these machines provide the freedom to customize products according to specific requirements.

Cost-Effective Manufacturing Solutions

Tube bending machines contribute to cost-effective manufacturing by minimizing material wastage and optimizing production processes. The precise control over the bending process ensures that each component meets exact specifications, reducing the need for rework and material adjustments.

Eco-Friendly Manufacturing Practices

In an era where sustainability is a key consideration, tube bending machines align with eco-friendly manufacturing practices. By minimizing material waste and optimizing energy consumption through automated processes, these machines contribute to a more sustainable and environmentally conscious approach to production.